PLAATO INSIGHTS PLATFORM

Industrial AI

empowering smart

beverage and liquids production

PLAATO’s data-driven AI empowers production facilities to elevate quality, cut costs by up to 30% and throughput by up to 20%.

400+ customers in 38 countries have

grown their business with PLAATO

Produce Better, with PLAATO

PLAATO’s brewing software gives breweries, distilleries, wineries, and Ready-To-Drink (RTD) manufacturers unparalleled analysis of their processes. This helps them improve consistency, experiment successfully, and scale their production with confidence.

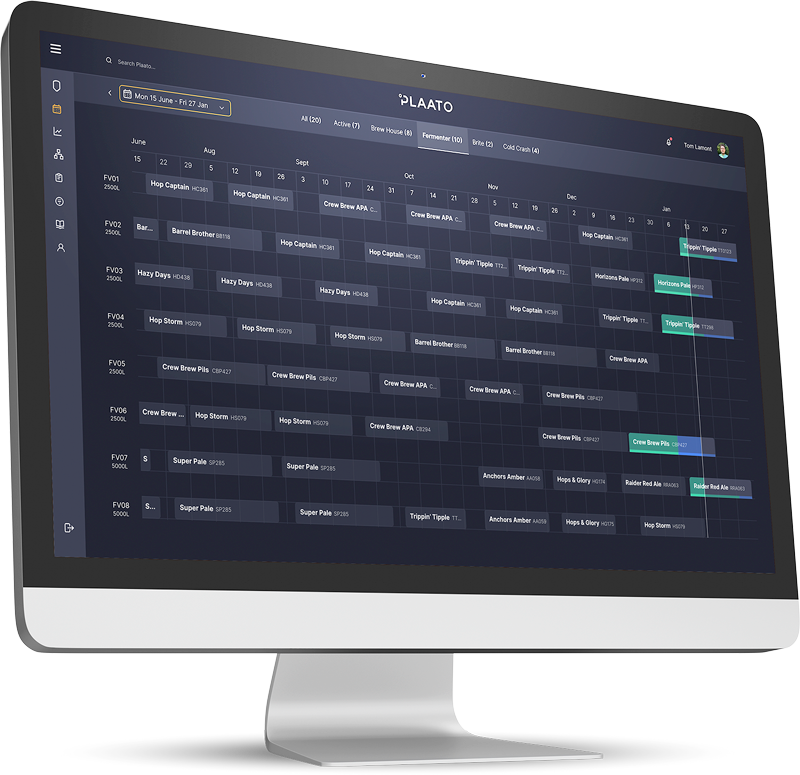

PLAATO Insights elevates every stage of beverage production from raw ingredient processing to final packaging. Powered by advanced AI, modern software, and the PLAATO Edge Gateway, PLAATO captures, connects, and analyzes all your operational data across past, present, and future performance.

Produce Smarter, with PLAATO

For teams focused specifically on fermentation, our Smart Fermentation solution delivers real-time visibility into gravity, temperature, flow, and other critical parameters.

With PLAATO, you can track, manage, and compare all your production data in one unified platform for every batch. This end-to-end visibility empowers you to improve product quality, increase efficiency, and maintain complete control across your entire beverage operation.

Unlocking savings: How PLAATO Insights supports industrial beverage producers

Through one small device, PLAATO Insights collects all your data across your entire production facility. It then analyzes it and enables you to spot bottlenecks, identify equipment issues, meet sales demands, and more: 24/7, 365 days a year. With all your data visible on mobile, web, and more.

All your production data in one place

Common challenges and pain points for beverage producers

In the beverage production industry, certain issues are commonly faced, from costs and resources to fermentation and inconsistent batch quality. However, with PLAATO’s software, these pain points can be eased, and you can ensure continuous, quality batches through insights and data. Here are some common issues faced by beverage production facilities, and how we can help.

Technical requirements

If your facility is running multiple PLCs across the production line, the PLAATO Edge gateway connects seamlessly to each system, delivering all your process data into one unified Insights platform.

Our Pro Sensors monitor fermentation by tracking key metrics, and are compatible with standard industrial fermentation tanks.

For more information on brewery requirements or setup, please contact us today, and our friendly team will be happy to help.

Key areas PLAATO can help with

Avoid issues before they grow, catch anomalies instantly, and reduce manual work through automated, intelligent data tracking.

Increase Throughput

PLAATO optimises production sequences, accelerates processing and cleaning, and identifies bottlenecks, idle time, and over-production ensuring smoother, faster workflows.

Maximize Yield and Minimise Waste

PLAATO pinpoints the optimal timing for each stage, detects process stalls or slowdowns, and continuously fine-tunes operations to improve yield and reduce losses.

Reduce Downtime

With early-warning analytics and predictive maintenance insights, PLAATO helps you address equipment issues before they disrupt production.

Benefits of PLAATO’s production software

With PLAATO’s software, you can enhance every stage of your process from mash-in to packaging, improving product quality, operational efficiency, and overall output.

-

Gain real-time visibility into critical stages such as mashing, lautering, boiling, whirlpooling, fermentation, conditioning, and packaging. Track the development and efficiency of every batch, enabling proactive decisions that prevent costly issues before they escalate.

-

PLAATO continuously monitors key parameters across brewhouse and cellar operations, helping you detect anomalies early. By identifying deviations in temperature, gravity, flow, or timing, you can intervene quickly and avoid inconsistent or spoiled batches.

-

Automated data collection and analysis significantly reduce manual checks throughout the brewhouse, cellar, and packaging line. This decreases labor hours, minimizes human error, and improves batch-to-batch consistency.

-

PLAATO integrates seamlessly with major management systems to create a smooth, cohesive workflow. Whether you use brewhouse automation tools, fermentation control systems, or production planning platforms, PLAATO connects it all.

Please contact us for more information. -

PLAATO’s software integrates with most major PLCs and sensor systems, including those controlling brewhouse operations, fermentation tanks, filtration, and packaging lines.

It also connects easily with ERP systems tailored for breweries.Custom integrations can be developed to match the unique configuration of your requirements, contact us for more information.

Integration Steps

Identify your ERP or automation system.

Confirm API or data-sharing capabilities.

Collaborate with PLAATO’s integration team to build a custom connector.

Our flexible approach ensures your entire production pipeline flows into one unified platform.

-

PLAATO provides robust recipe management tools to ensure consistency, quality control, and scalable production.

Monitor key variables throughout brewhouse and cellar stages, experiment confidently with new ingredients, and receive automated alerts for critical steps to support a smooth, structured workflow.Many production sites rely on PLAATO for recipe management, contact us to explore how we can support you.

-

PLAATO adheres to relevant data protection regulations to ensure your operational and product data is secure.

Data is encrypted end-to-end, and regular penetration testing ensures industry-standard security practices across our infrastructure.You can operate with confidence knowing your data is fully protected. For more information on data storage and security, contact us anytime.

This gives you complete confidence that when you use our products, your data is protected. For more information on how we collect, store, and protect your data, contact us today.

-

PLAATO meets industry regulations, standards, and quality frameworks so that, when you use our products and services, your compliance needs are met.

What customers are saying about PLAATO

“PLAATO Pro/Smart Fermentation is the most convenient piece of technology that a brewery can buy….. of any size!”

Samir Pandya, QA Manager, Sycamore Brewing (40,000 hL)

Why choose PLAATO?

PLAATO gives beverage producers real-time visibility across every stage of production, from mash to packaging, helping you improve consistency, optimise every batch, reduce waste, and maintain the highest beer quality.

All your production data is collected, connected, and stored in one central platform, making it easy to compare batches, refine processes, and make informed decisions that strengthen future products.

We are experts in beverage production technology and automation. Contact us today to see how PLAATO can support your operation.

FAQs

-

PLAATO monitors key brewing metrics such as mash temperature, lautering efficiency, boil activity, whirlpool flow, gravity, fermentation temperature, tank pressure, cooling performance, filtration flow, and packaging line behaviour, giving you end-to-end visibility across your entire brewhouse and cellar.

-

Yes. PLAATO supports all brewery models from craft and microbreweries to large-scale production, across lagers, ales, sours, high-gravity brews, and specialty beers.

-

PLAATO monitors key process metrics such as gravity, temperature, flow, and maturation conditions across fermentation, distillation, and ageing stages.

-

Yes, PLAATO’s distillery software supports the production of any kind of spirit, including whisky, rum, vodka, gin, tequila, and more.

-

Absolutely. PLAATO integrates seamlessly with brewhouse PLCs, cellar automation, sensors, and existing control systems. If you use a specific platform, get in touch and we’ll confirm integration options.

-

Yes. PLAATO covers the full brewery workflow: mash, lauter, boil, whirlpool, cooling, fermentation, conditioning, filtration, and packaging giving you a complete overview no matter how many tanks or lines you operate.

-

PLAATO is built for breweries, distilleries, wineries and RTD production companies of all sizes, with flexible deployment designed to grow as your production does, whether you’re a small craft operation or a high-capacity facility.

-

No formal training is required. The dashboard is user-friendly, and PLAATO provides support and guides for installation, monitoring, and maintenance.

-

Installation for Smart Fermentation is plug-and-play. The sensor mounts to the tank via a 1.5” tri-clamp, and the Edge Gateway connects to your PLC network for automated data gathering and cloud access.

Let’s talk!

Be the master of your production data with PLAATO

Book a call to get to know our products better and to find what’s the right fit for you and your goals right now, or for the future.