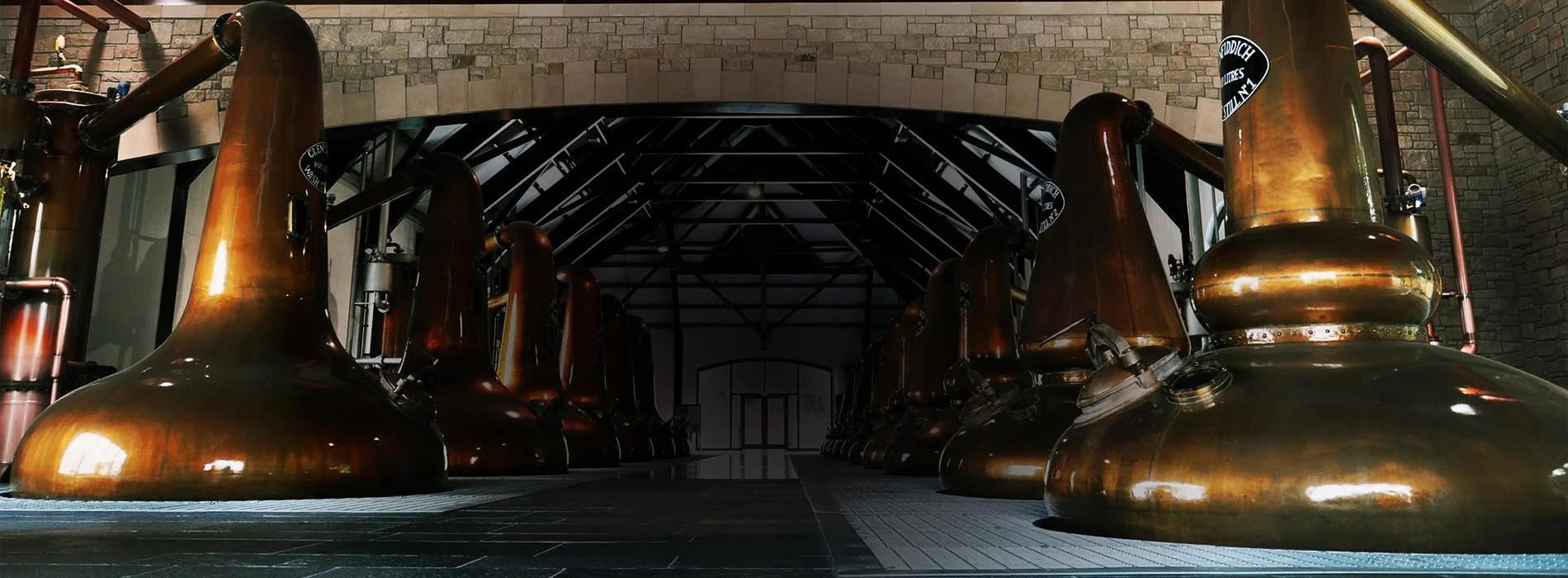

PLAATO INSIGHTS PLATFORM

Unlock Your

Distillery Data With AI

At PLAATO, we use data-driven AI technology to help distilleries work smarter, craft exceptional spirits, and reduce costs by up to 30%. Plus, increase yield and throughput by up to 20%.

400+ customers in 38 countries have

grown their business with PLAATO

Distil smarter, and better, with PLAATO

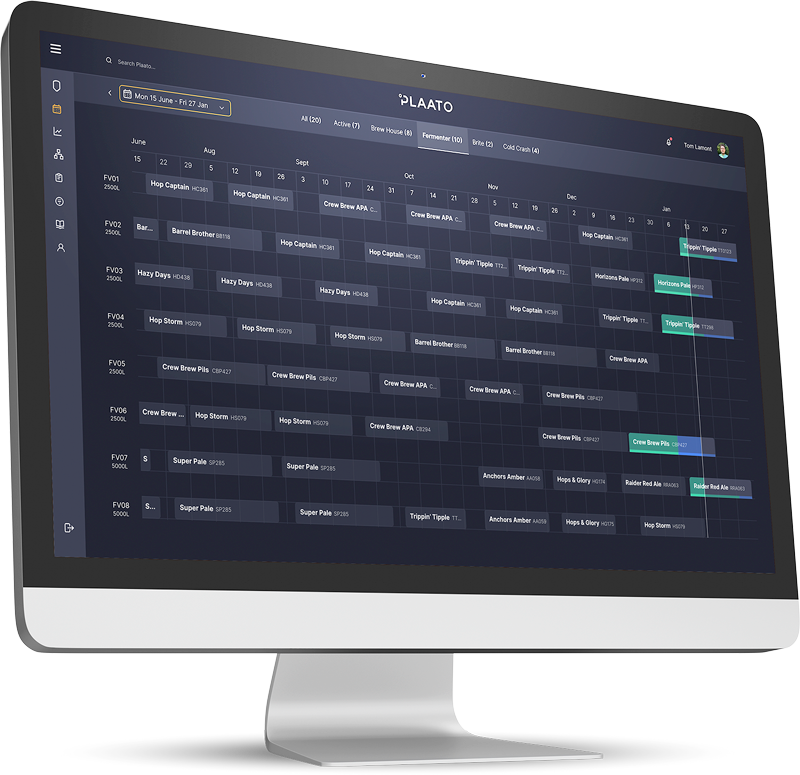

Our PLAATO Insights product improves everything from your malting to your bottling process. We use the latest AI and software technology to capture and analyze all your metrics for you: past, present and future. Or, if you want to focus just on your fermentation, our Smart Fermentation product gives you your gravity, temperature, flow and more in real-time.

With our distillery software you can track, manage, and compare all your data in one place for every batch. This provides you with complete visibility throughout the entire process. The result? Higher quality spirits, more efficient operations, and better control.

Unlocking savings: How PLAATO Insights supports industrial beverage producers

Through one small device, PLAATO Insights collects all your data across your entire distillery. It then analyzes it and enables you to spot bottlenecks, identify equipment issues, meet sales demands, and more: 24/7, 365 days a year. With all your data visible on mobile, web, and more.

All your distillery production data in one place

Common challenges and pain points for distilling

In the spirit industry, certain issues are commonly faced by distilleries, from costs and resources to fermentation and inconsistent batch quality. However, with PLAATO’s distillery software, these pain points can be eased, and your distillery can ensure continuous, quality batches through insights and data. Here are some common issues faced by distilleries, and how we can help.

Distillery technical requirements

If your distillery has a PLC system, the PLAATO Edge gateway can be installed to collect data and transmit it directly to the PLAATO Insights platform. This ensures all your data is in one place.

PLAATO can be implemented in distilleries using the same hardware and software setup as breweries. Our Pro Sensors monitor fermentation by tracking key metrics, and are compatible with standard distillery fermentation tanks.

For more information on distillery requirements or setup, please contact us today, and our friendly team will be happy to help.

Key areas PLAATO can help with

Avoid issues before they grow, catch anomalies instantly, and reduce manual work through automated, intelligent data tracking.

Increase Throughput

Optimizes sequences, speeds up processes, cleaning, detects bottlenecks, idling, over-production and more.

Maximize Yield and Reduce Waste

Pinpoints optimal timing for processes, detects stalls or sluggish operations, and continuously optimizes your production stages.

Reduce Downtime

Delivers early warning analytics on your equipment, as well as predictive maintenance.

Benefits of PLAATO’s distillery software

With PLAATO’s distillery software, you can experience a host of benefits when it comes to the distillery process, product quality, and the efficiency of your operations.

-

With real-time insights into the mashing and fermentation process, you can track the efficiency and development of each batch. This allows you to make proactive decisions to avoid big problems.

-

With continuous tracking, PLAATO helps you identify anomalies so that you can act quickly to prevent bad batches.

-

Our automated data collection and analysis software for distilleries helps reduce manual checks whilst streamlining operations. This also reduces the risk of human error, meaning more consistent batches.

-

PLAATO’s distillery software integrates with most major PLCs and sensor brands. It is also fully capable of connecting with any ERP software, including those specifically tailored for distilleries or RTD manufacturers. Custom integrations can be developed to meet the specific operational needs of your distillery.

Please contact us for more information. -

Identify the ERP system used by the distillery.

Confirm API or data exchange capabilities.

Collaborate with PLAATO’s integration team to develop a custom API connector.

We ensure our approach to software integration is flexible to help distilleries bring all their production data to one centralised platform. -

PLAATO software integrates seamlessly with various brewing and distilling management software to ensure a cohesive and efficient workflow.

-

PLAATO’s distillery software helps you manage recipes to ensure consistency, quality control, and efficient scaling. You can monitor key variables throughout the distilling process, allowing you to experiment easily with new ingredients, and automate notifications for key steps to ensure your workflow is smooth and clear for everyone involved.

Many of our clients use PLAATO’s distillery software to manage recipes, so if you’d like to discuss how we can help you, contact us now.

-

At PLAATO, we comply with relevant data protection laws and regulations to ensure that the data that you provide when using our sites, products, and services, and the data collected by our sensors, is collected securely over encrypted channels to prevent unauthorised access. We carry out regular penetration testing and ensure industry best practices in everything we do, from operations to infrastructure.

This gives you complete confidence that when you use our products, your data is protected. For more information on how we collect, store, and protect your data, contact us today.

-

PLAATO meets industry regulations, standards, and quality frameworks so that, when you use our products and services, your compliance needs are met.

What customers are saying about PLAATO

"I've really appreciated having PLAATO for the last year as it's enabled me to have remote visibility, and ensure my ferms are on track. I've been able to experiment with different yeasts and see exactly what's happening in the tank as a result. It's been important to see that the graphs are the same/similar each time as I then know my process is faultless."

The Walrus Distillery, David Robertson

Why choose PLAATO?

PLAATO gives distilleries real-time visibility across every stage of production, helping to improve consistency, optimise batches, and reduce waste whilst ensuring a high-quality product.

We collect data and store it all in one place so that you can easily manage batch after batch. We are experts in technology for the distilling industry, so contact us today to see how we can help you.

FAQs

-

PLAATO monitors key process metrics such as gravity, temperature, flow, and maturation conditions across fermentation, distillation, and ageing stages.

-

Yes, PLAATO’s distillery software supports the production of any kind of spirit, including whisky, rum, vodka, gin, tequila, and more.

-

Yes, we make it easy for teams to adjust to processes with our integratable software. If you have a specific software in mind, contact us to see how we can help.

-

Yes, we support every part of the production process so you get to see the whole picture, regardless of how many tanks you have.

-

PLAATO is suitable for craft distilleries and larger-scale production, offering flexible deployment that grows with your operation.

Let’s talk!

Be the master of your distillery with PLAATO

Book a call to get to know our products better and to find what’s the right fit for you and your goals right now, or for the future.